Lower the Pressure to Keep Your Compressed Air System Healthy

Just as lowering blood pressure reduces stress on your heart, lowering your compressed air pressure reduces stress on the heart of your plant, the air compressor.

Manufacturing processes require adequate compressed air pressure to properly function. To avoid problems, production personnel who often believe that “more is better” will increase the pressure, but elevating pressures to higher levels than required increases input power consumed by the motor driving the compressor. In addition to this, the higher pressure causes higher compressed air flow consumed by unregulated air demands, such as air leaks, and thus further increases energy and other associated costs. Training at the Compressed Air Challenge (CAC) has addressed some air system problems, such as excessive pressure drop, that force plant air pressure to be maintained at a higher than necessary pressure.

“Pressure drop” is a term used to characterize the reduction in air pressure from the compressor discharge to the actual point of use. Pressure drop occurs as the compressed air travels through the restrictions within the treatment and distribution system. A healthy and properly designed system should have a pressure loss of less than 10% measured from the final compressor room receiver tank to the point of use.

Rule of Thumb for Excess PSI

Excessive pressure drop will result in poor system performance and excessive energy consumption. Flow restrictions caused by any component require higher operating pressures than are needed, resulting in higher input power and energy consumption. Minimizing pressure differentials in all parts of the system is an important part of improving the efficiency of a system. Higher compressor discharge pressure in rotary screw compressors will increase the input power to the motor by approximately 1% for each 2 psi of added pressure in a 100-psig system.

A pressure drop in the distribution system and in hoses, tubing, quick couplers, and flexible connections at end-use equipment usually results in lower operating pressure and poor performance at critical points of use. Instead of increasing the compressor discharge pressure to overcome the pressure drop, a more effective and efficient method is to reduce the pressure drops in the system and thereby improve point-of-use performance. This solution may cost a few hundred dollars in one-time costs; however, increasing the compressor discharge pressure or adding extra compressor capacity to boost system pressure often results in thousands of dollars in increased energy costs.

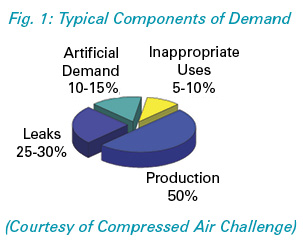

Artificial Demand

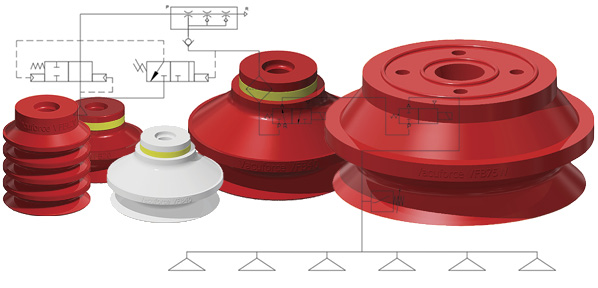

Elevating the entire plant system pressure increases air consumption at locations such as leaks, open blowing, and production applications if they are unregulated (Fig. 1). The added flow of compressed air at elevated pressure is termed “artificial demand” and substantially increases energy consumption. Equipment should be specified and operated at the lowest efficient operating pressure, thus allowing lower system pressures and reduced artificial demand.

Elevating the entire plant system pressure increases air consumption at locations such as leaks, open blowing, and production applications if they are unregulated (Fig. 1). The added flow of compressed air at elevated pressure is termed “artificial demand” and substantially increases energy consumption. Equipment should be specified and operated at the lowest efficient operating pressure, thus allowing lower system pressures and reduced artificial demand.

What Causes Pressure Drop?

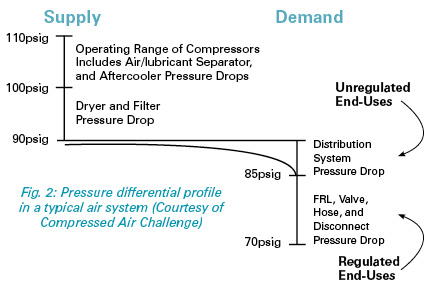

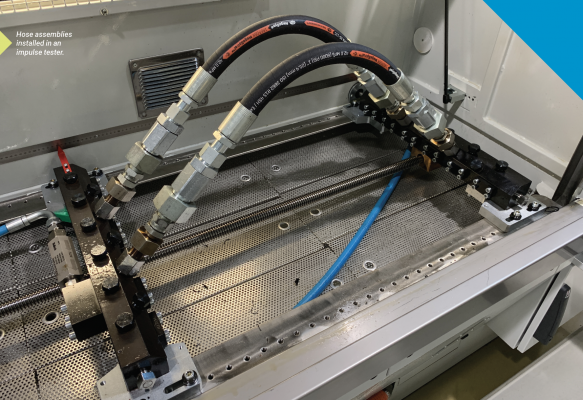

Any type of obstruction or restriction in a system will cause resistance to air flow and cause a pressure drop. In the distribution system, the highest pressure drops are usually found at the points of use at the end of the compressed air system, including undersized hoses, tubing, quick-disconnect couplers, and filters, regulators, and lubricators (FRLs). On the supply side of the system, main-line dryers and filters can be significant causes of pressure drops (Fig. 2).

Plan for Peak Flows

The maximum pressure drop between the supply side and the points of use will occur when the compressed air flow rate is highest. System components should be selected based upon these peak conditions, not average, and the manufacturer of each component should be requested to supply pressure drop information under these conditions. When selecting filters, remember that they will get dirty. Dirt-loading characteristics are also important selection criteria in maintaining adequate pressure over the long term. Large end-users that purchase substantial quantities of components should work with their suppliers to ensure that products meet the desired specifications for differential pressure.

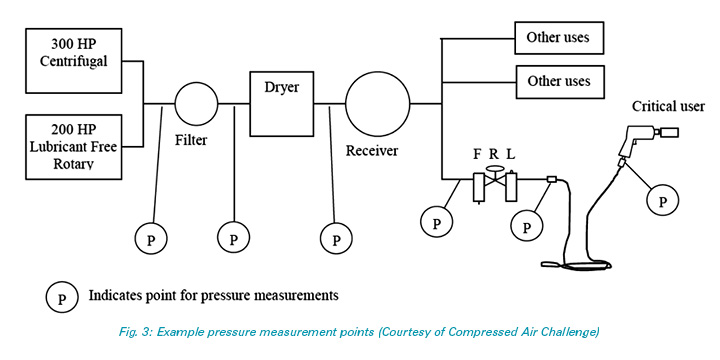

Measure the System

The distribution piping system often is diagnosed as having a high pressure drop because a poorly selected point-of-use pressure regulator cannot sustain the required downstream pressure. If such a regulator is set at 85 psig, and the regulator and upstream filter have a pressure drop of 20 psi, the system upstream of the filter and regulator would have to maintain at least 105 psig. The 20-psi pressure drop may be blamed on the system piping rather than on the components. In many cases, undersized valves or connections to the end use can also be the cause of excessive pressure drops. The correct diagnosis may require pressure measurements at different points in the system to identify the component(s) causing the high pressure drop. In this case, the size of the filter regulator and/or downstream connections may need to be increased, not the main line piping (Fig. 3. Click on image to enlarge).

Effects of Reducing Pressure

Reducing and controlling the system pressure downstream of the primary receiver can result in a total system reduction in energy consumption of 10% or more. Reducing system pressure, like lowering your blood pressure, also can have a healthy cascading effect in improving overall system performance. Other benefits include reduced leakage rates, increased system capacity, and increased compressor life. However, a reduced system-operating pressure may require modifications to other components, including pressure regulators, filters, and the size and location of compressed air storage. Lowering average system pressure requires caution since large intermittent increases in demand can cause the pressure at points of use to fall below minimum requirements, which can cause equipment to improperly function. These problems can be avoided with careful matching of system components, controls, and increased compressed air storage capacity.

Specifying Efficient Equipment

For applications using significant amounts of compressed air, it is recommended that equipment be specified to operate at lower pressure levels. The added cost of components, such as larger air cylinders, usually will be quickly recovered from resulting energy savings. Some plants specify end-use equipment to operate at an average system pressure, which can eventually result in higher operating costs. First, the point-of-use installation components, such as filters, pressure regulators, and hoses, will be installed between the system piping and the end-use equipment. Second, leaks will occur and filters also will get dirty, both resulting in lower pressure. This should be anticipated in specifying the available point-of-use pressure.

If an individual application requires a higher pressure, instead of raising the operating pressure of the whole system, it may be best to replace or modify this application. It is also important to check if OEM manufacturers are including pressure drops in filters, pressure regulators, and hoses in their pressure requirements for end-use equipment or if the stated pressure requirements are upstream or after those components. A typical pressure differential for a filter, pressure regulator, and hose is 7 psid, but it could be much higher in poorly designed and poorly maintained systems.

When demand pressure has been successfully reduced and controlled, attention then should be turned to the compressor control set points to obtain more efficient operation. It may then be possible to unload or shut off a compressor to further reduce energy consumption.

Strategies for Minimizing Pressure Drop

Minimizing pressure drop requires a systems approach in design and maintenance of the system. Air-treatment components, such as dryers and filters, should be selected with the lowest possible pressure drop at specified maximum-operating conditions. When installed, the recommended maintenance procedures should be followed and documented.

In summary, additional ways to minimize pressure drop are as follows:

- Properly design the distribution system.

- Select dryers and filters having the least possible pressure drop for the rated conditions.

- Maintain air-filtering and drying equipment.

- Specify pressure regulators, lubricators, hoses, quick couplers, and other connections having the best performance characteristics at the lowest pressure differential.

Keep the pressure on, but not too much!

* Information for this article was obtained from Compressed Air Challenge publications.

Thanks for your tips about managing a compressed air system. I like your analogy about how having too much pressure in your compressed air piping can put too much stress on your air compressor, just like your blood pressure and your heart. I like how you also talk about making sure that you look at the efficiency of your compressor system and pipes instead of increasing the compressor discharge. I’ll keep those tips in mind. Thanks.

What would be the effect on compressor life if the working pressure is increased by 20%?