New Gear Pump Series Reduces Noise and Vibration

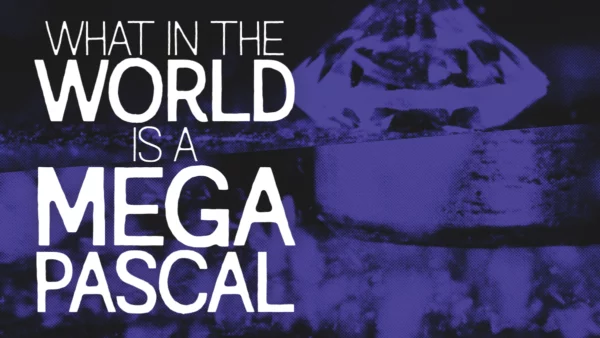

ELIKA, Marzocchi’s new proposal for the gear pumps market, is designed for applications that require low noise levels. The use of this gear pump eliminates adverse noise effects on humans and on the surrounding environment. It also reduces the noise level by an average of 15 dBa compared with a conventional external gear pump.

One of the main frontiers of development of industrial products is the reduction of noise and vibrations. These requirements have increased considerably of late due to the strict environmental regulations introduced in industrialized countries. Noise emanating from industrial vehicles was once seen as a much less pressing concern than limiting harmful emissions, but the EU already had extensive legislation in place designed to reduce NVH (noise, vibration, harshness) and provide a much more comfortable environment for vehicle operators, not to mention anyone within hearing distance. There are two relevant NVH directives in the EU: 2000/14/EC, which came into force in 2001 and focuses on noise emissions; and 2002/44/EC, which came into force in 2005, setting standards for vibration. Demand for quieter products is particularly high in Europe and North America.

It is now clear that operating with noisy machines has become a burden, so attention to this parameter has increased. Noise and vibration issues inevitably involve the interaction between the components of a hydraulic circuit, or between components and different parts of structure. There are two different approaches to noise reduction: one is to take measures to attenuate NVH propagation by applying isolators and dampers to major noise and vibration sources. Often these palliative modifications only partially solve the problem—in addition to adding cost, weight, and bulk to the final product, as they are only effective under certain conditions and only for certain frequencies. The second, more efficient, approach is to tackle the problem at the source, designing the machine to be as quiet as possible using low-noise technologies. The use of alternative technology to lower the level of noise is normally the cheapest and gives the greatest results. This forward-looking approach may also offer economies compared with the cost of fixing a problem after the event.

Marzocchi Pompe’s R&D department is equipped with experimental test benches to acquire mechanical, hydraulic, acoustic, and vibration performances, and durability test benches capable of simulating the toughest working conditions. Gear pump noise has two distinct origins—mechanical and hydraulic. The mechanical noise is what can be expected from any pair of gears, and depends mainly on the degree of precision and the surface finish of the gear wheels. The hydraulic noise is mainly generated from pressure peaks that arise from entrapment of the fluid between the crest and root of the gear teeth. During the delivery phase, the trapped fluid reaches very high pressure spikes, which cause the noise, vibration, pressure ripples, and mechanical stress.

There are various methods that can reduce the effect of entrapment in the external gear pumps. Marzocchi Pompe examined and studied several prototypes to verify the characteristics of each solution until reaching a real solution to the noise problem: the accurate design of special discharges on bushings can slightly reduce the phenomenon without completely eliminating the cause. To be able to completely eliminate the pressure peaks on the entrapped volume, the size of the discharge should be such as to adversely affect volumetric efficiency. For this reason, the conformation of bushing discharges is a compromise between noise and volumetric performances.

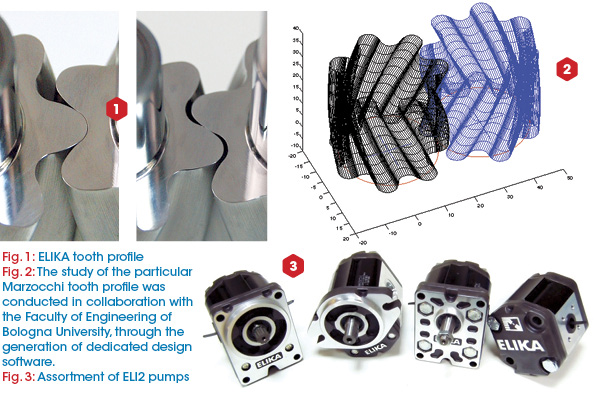

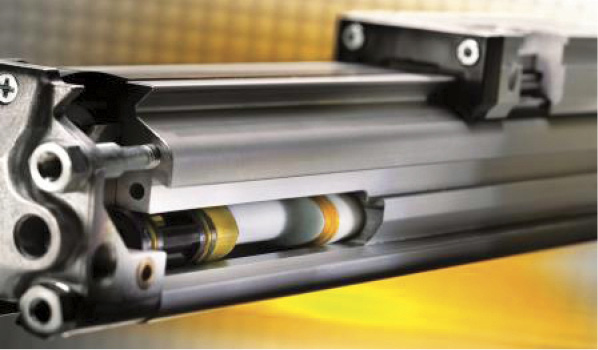

The ELIKA gear pump was developed in response to these applications that require low noise levels. ELI2 is the first series in this trademark-registered product family and includes pumps with displacement from 7 to 35 cm3/rev and are perfectly interchangeable with the standard gear pumps ALP2 and GHP2 series. The maximum operating pressures are similar to those of GHP2 and extend up to 300 bar. The heart of this product is its particular shape, which eliminates encapsulation typical of normal gear pumps, deleting the main source of noise and vibration. The total elimination of the encapsulated volume produces a significant reduction in pressure oscillation that causes noise and vibration transmitted to the other components connected to the pump, such as hoses, tanks, and valves. During the meshing phase, there exists a moment when the point of the teeth profile comes into contact with the other toothed wheel; there is always a separation line between the high and low-pressure area, whatever the helix angle.

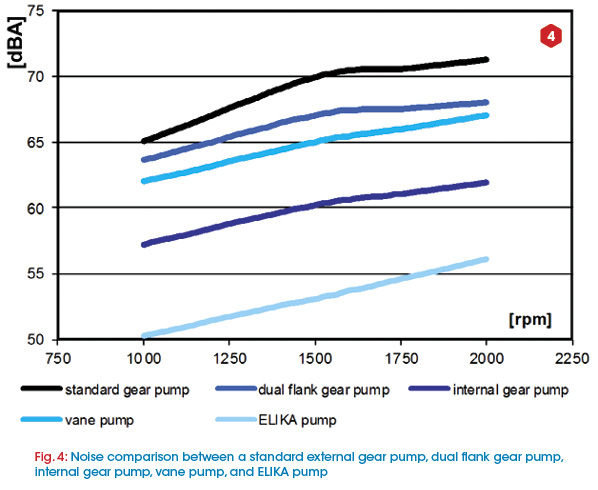

The study of the particular Marzocchi tooth profile was conducted in collaboration with the Faculty of Engineering of Bologna University through the generation of dedicated design software. The experiments carried out led to the definition of a specific tooth profile able to get the best performances and acoustic characteristics. The helical tooth design ensures the continuity of motion, which reduces the pressure oscillations. The low number of teeth greatly lowers the fundamental frequency of the pump noise. ELIKA reduces the noise level by an average of 15 dBa compared with a conventional external gear pump.

ELIKA, as a common external gear unit, consists of a pair of gears supported in bearing bushings and a case with front and rear cover. The special bearings material ensures excellent resistance to galling, especially at low speed. Axial forces induced by the helical teeth are optimally balanced in all operating conditions by the axial compensation system integrated in the pump cover. Specific compensation areas into flange and cover, insulated by special gaskets reinforced with anti-extrusion, allow for fully free axial and radial movement of the bushings, which is proportional to pump operating pressure. In this way, internal leakage is dramatically reduced, ensuring good volumetric and mechanical performance, as well as proper lubrication of the pump’s moving parts.

The internal leakage that generally flows to the outlet from the inlet, overheating the pump components, is practically eliminated in the pump, increasing reliability. This feature makes the pump suitable for working operations with low speed and high pressure.

In many hydraulic applications today, precise electronic control is enabling lower speed operation at higher pressures, which is a demanding mode of operation for gear pump products. ELIKA is particularly suitable for these applications, as its features are an important priority for designers of plastic injection machines, electric vehicles, as well as lifting and materials-handling equipment, electrical aerial work platforms, warehouse and waste-compacting trucks, and other mobile equipment operating at night in residential areas. The pump is also suitable for industrial machine tool applications, such as presses, milling machines, saws, lathes, and marine equipment.

When comparing the characteristics of the ELIKA gear pump with other kinds of volumetric pumps, it is possible to see a very high field of use, like the rotation speed, work pressure, and viscosity range. The very low noise level generated makes this small-size product suitable for applications where screw pumps, vane pumps, and internal gear pumps are generally used.

The black anodizing pre-processing of components, as well as the simple construction, small size, and high performance of the ELIKA pumps makes them stand out in the market. The pumps are available in both unidirectional clockwise or counter-clockwise rotation; all commercial versions of standard gear pump flanges group 2 are also available. They are available in displacements between 7 and 200 cm3/rev, with three main families: ELI2 includes pumps with displacements from 7 to 35 cm3/rev, ELI3 with displacements from 20 to 87 cm3/rev, and the biggest family ELI4 with displacements up to 200 cm3/rev. They are also available in multiple stage configurations.

It’s nice to see that gear boxes are getting to be much quieter and smoother. My gear pump has started to make very strange noises and it is very concerning. I definitely think that I should consider looking for a professional that could replace it with a new advanced model.