Sheet Metal Vacuum Gripping

By Dane Spivak, Engineering Manager, Davasol Inc.

A flat smooth surface with plenty of area is an ideal product for vacuum gripping or pick and place. Products such as sheet metal provide easy cup sealing and plenty of area for suction cup placement. Putting together a system that works is easy enough, but designing an efficient system that is properly engineered can provide significant savings in cost, energy consumption, maintenance, and reliability.

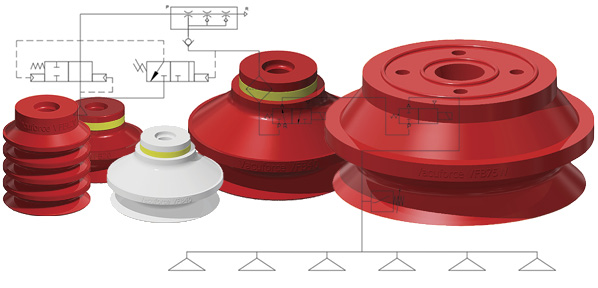

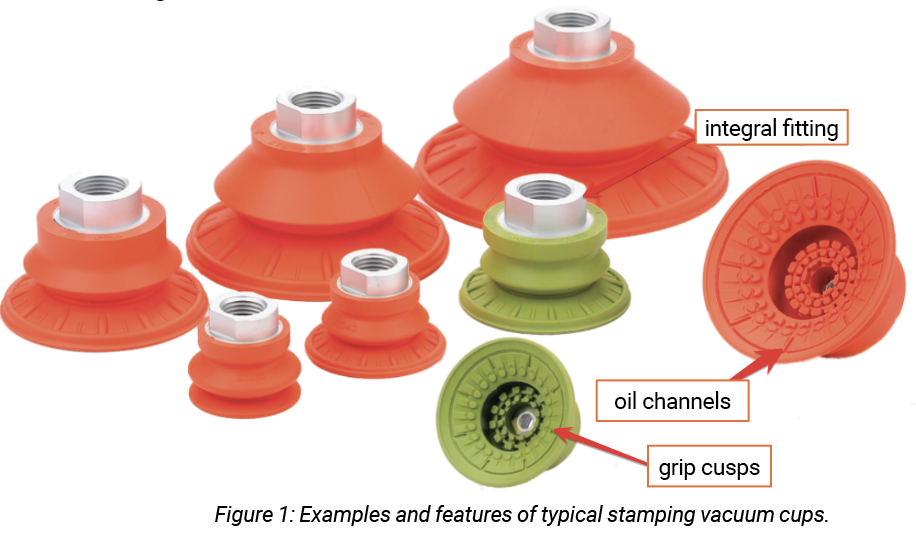

There are specific vacuum cups designed for the steel-stamping industry that are referred to as heavy-duty metal-stamping cups, or a variation of those words. Stamping cups tend to be flat or single bellows, have an integral metal fitting for rigidity, and have internal ribs for oil channels and increased frictional gripping force. These suction cups are usually made in nitrile or polyurethane materials. Polyurethane is an ever-popular choice as it typically provides longer cup life and is nonmarking. Nitrile is adequate in these categories as well, so some users will stick with this material that they have been using for some time and that can be sourced at a lower cost. Other manufacturer-specific materials are also available. Figure 1 shows an example of conventional stamping cups and their features.

Stamping cups are usually round or oval. Round is the go-to shape; oval is used for narrow points or any target areas where a round cup would not fit or seal. Because of the nature of metal sheets, which warp and bend across their surface and have manufactured curves formed from press operations, single short-bellows cups are used to provide height and angular compensation as well as allow the cup lips to conform and seal against uneven locations. Flat cups are useful when sheets are relatively level, allowing for a sturdier grip. If need be, spring-loaded level compensators can always be used as a vertical buffer, as they often are with both flat and bellowed cups.

The gripping forces in many steel-stamping applications, such as sheet pick and place, are overkill. The reason is that an array of cups spread out across the surface is required for a balanced and stable grip. When gripping large surface areas, particularly thin sheet products, it is important to have many smaller cups at multiple points instead of fewer cups with bigger diameters. The goal is to spread the gripping force, but when doing so, the cup diameters should be sized appropriately so they provide a reasonable and safe gripping force without exceeding needs. Using the right cup size can save considerable cost on parts and energy use when considering the vacuum generators required.

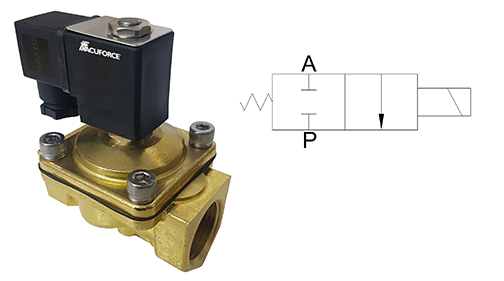

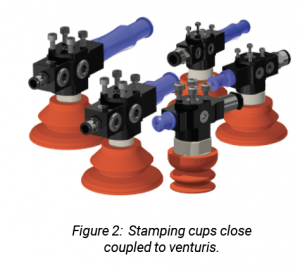

The traditional vacuum system for pick and place in metal stamping is one air-powered venturi generator close coupled to a single suction cup, as shown in figure 2. This allows for each cup to be fully independent and simplifies installation for the user or machine builder. It is an easy, effective way to get the job done, though the approach has its challenges, including excessive air use, lack of filtration, and managing each as an individual system.

The traditional vacuum system for pick and place in metal stamping is one air-powered venturi generator close coupled to a single suction cup, as shown in figure 2. This allows for each cup to be fully independent and simplifies installation for the user or machine builder. It is an easy, effective way to get the job done, though the approach has its challenges, including excessive air use, lack of filtration, and managing each as an individual system.

The alternative and solution to the single-cup-per-venturi conundrum is a centralized system in which a larger venturi powers and controls a set of cups, or a vacuum-pump and vacuum-valve system to do the same. Larger venturis allow for using multistaged units that use air more efficiently, allowing a reduction in their consumption. In a centralized system, the external plumbing creates room for installation of a proper vacuum filter to protect the vacuum generator. Having a single vacuum source is easier to manage and maintain with controls, sensors, and other system components. Motor-driven vacuum pumps are not the most popular in stamping since pumps cannot be mounted to the robot arm, and they require vacuum valves to control the cups. In this case there are extra pieces, adding to the work, and higher costs that are generally not worth it for many facilities with an abundance of compressed air available. Centralized vacuum systems have their benefits, but they typically require a larger variety of parts for plumbing and rely on all cups sealing properly.

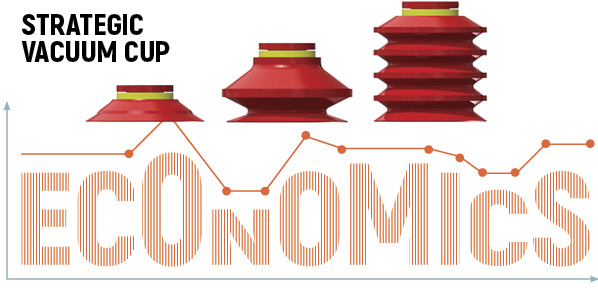

For cups potentially leaking in centralized systems, there are techniques to isolate them if they do not seal properly. Products such as velocity fuses, shuttle valves, or self-closing valves shut off vacuum from cups that do not seal against the product. The valves close based on the in-rush of flow from the leaking cups. Figure 3 illustrates a self-closing valve’s components and functionality. With one of these on each cup, the system becomes universal in a sense because any number of cups can grip the product or shut independently while still achieving maximum vacuum-level pressure. These types of system designs require the cups to contact the product first before vacuum is turned on to ensure they do not close prematurely. Additionally, if the sensors are connected into the vacuum system, it can be difficult to measure lifting force and understand which cups are gripping the product. A vacuum sensor would be required on each cup between the self-closing valve and cup to get a true measurement.

For cups potentially leaking in centralized systems, there are techniques to isolate them if they do not seal properly. Products such as velocity fuses, shuttle valves, or self-closing valves shut off vacuum from cups that do not seal against the product. The valves close based on the in-rush of flow from the leaking cups. Figure 3 illustrates a self-closing valve’s components and functionality. With one of these on each cup, the system becomes universal in a sense because any number of cups can grip the product or shut independently while still achieving maximum vacuum-level pressure. These types of system designs require the cups to contact the product first before vacuum is turned on to ensure they do not close prematurely. Additionally, if the sensors are connected into the vacuum system, it can be difficult to measure lifting force and understand which cups are gripping the product. A vacuum sensor would be required on each cup between the self-closing valve and cup to get a true measurement.

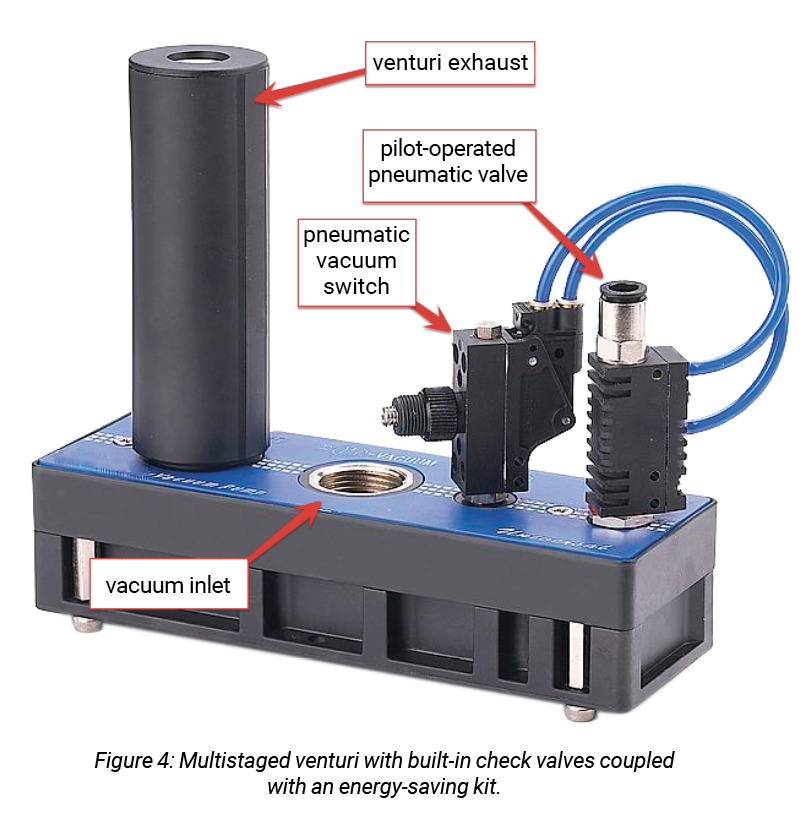

Revisiting compressed-air consumption, venturis use compressed air to generate vacuum, and the total consumption is correlated to how much time the venturi runs. Vacuum gripping flat smooth surfaces creates an excellent opportunity to save air because the venturis can run to charge up the vacuum then shut off once the vacuum level reaches its set point. Then check valves and self-closing valves in the system lock in and maintain the vacuum. Should the vacuum level drop, the venturi will turn on and charge up the system. Figure 4 illustrates an example of a venturi coupled with an air energy-saving kit consisting of the switch and pilot valve. This technique allows for the venturi run time to be reduced to a fraction, as it can remain off for all the pick-movement cycle in a pick-and-place application, and much longer in a vacuum hold-down type of process. It also works well with products such as the self-closing valve. Energy-saving parts are inexpensive and easy to use, which makes them very attractive to users.

Metal-stamping vacuum gripping applications offer the convenience of a simple and reliable system. However, cup selection and the use of venturis can greatly impact cost, efficiency, and energy use. Talk to a professional to find out which design is best for your application.

This article is the opinion of the author, Dane Spivak of Davasol Inc., an industrial brand management firm with many clients. One of Davasol’s clients, Vacuforce LLC, based in Indianapolis, partners with the author on this article. Contact Dane Spivak at dspivak@davasol.com.