Choosing a Shop Air Compressor: Reciprocating or Screw Type?

That pounding feeling in your brain may not be a migraine headache; it could be the piston-style reciprocating compressor pounding away in the corner of your shop. These units are often noisy, inefficient at full load compared to screw compressors, and produce hot, oily compressed air that is hard to dry and filter. Newer screw-type compressors, on the other hand, are quieter, can run at full loads for long periods of time, and produce cooler, cleaner air. But in a shop environment, caution must be exercised in replacing reciprocating compressors with screw-type units, or you may end up paying additional unexpected costs on your power bill.

That pounding feeling in your brain may not be a migraine headache; it could be the piston-style reciprocating compressor pounding away in the corner of your shop. These units are often noisy, inefficient at full load compared to screw compressors, and produce hot, oily compressed air that is hard to dry and filter. Newer screw-type compressors, on the other hand, are quieter, can run at full loads for long periods of time, and produce cooler, cleaner air. But in a shop environment, caution must be exercised in replacing reciprocating compressors with screw-type units, or you may end up paying additional unexpected costs on your power bill.

The reason for this warning is the way most screw compressors operate under typical shop flow profiles. In a repair or service shop environment, the compressed air flow is usually very low, on average, with high intermittent peak flows when large compressed air-operated tools, such as impact wrenches, or other tools are used. It is not uncommon to see average flows in the range of 5 to 15% of the installed compressor capacity. This characteristic is not a problem for reciprocating compressors because they naturally operate in start/stop mode, which is a quite efficient mode of operation. For example, for average flows of 10%, a start/stop compressor will run 10% of the time, and be off 90% of the time. In this case, the average power consumption would be 10% of the full-load power of the compressor.

But screw compressors operate a little differently. The most common mode of operation for a screw compressor is load/unload mode, where the compressor alternates between the loaded condition, producing full-output capacity while consuming full power, and the unloaded condition, where the compressor produces zero flow yet stays running while consuming about 35% of its full-load power. It is this unloaded power that can separate a screw from a reciprocating compressor in terms of energy efficiency.

For example, a 15-hp reciprocating compressor may consume 12.5 kW while producing its full load of 55 cfm of compressed air. The average power consumed by this compressor when loaded at 10% capacity and running start/stop would be 1.25 kW. A similar-sized screw, on the other hand, may consume 12.5 kW fully loaded while producing 60 cfm of compressed air, making it more efficient at full load. But if its unloaded power is about 35% of full load, it would consume 4.4 kW during all its unloaded run time. If this compressor replaced the reciprocating compressor, it would be fully loaded about 9% of the time because it produces more air. The average kW consumed while in the loaded condition would be about 1.13 kW, which is less than the reciprocating compressor; however, if allowed to run unloaded the remaining 91% of the time, the average unloaded power consumption would add up to another 4.0 kW. Therefore, under these unloading conditions, the screw would consume a total of about 5.13 kW compared to the 1.25 kW of the reciprocating unit, or about four times as much.

Why do screws run load/unload instead of start/stop? It has to do with the number of motor starts allowed. Having a heavy screw element on the end of the motor shaft increases the starting current required by the compressor motor. Motors are typically allowed only a certain number of starts per hour to prevent the windings from overheating, with the number depending on their size and the inertial loading on their shaft. For a 15-hp motor, the typical maximum number of starts would be 8 to 10 per hour. For larger motors (over 250 hp), only one start per hour may be allowed, or perhaps less depending on the starting method.

Compressor manufacturers usually use a one-size-fits-all policy when it comes to the compressor controls. One of the duties of the controls is to protect the motor by limiting the starts per hour. Often the controls used by large compressors are the same as the ones installed on small compressors, which means the small compressors are often limited to the same low number of starts per hour.

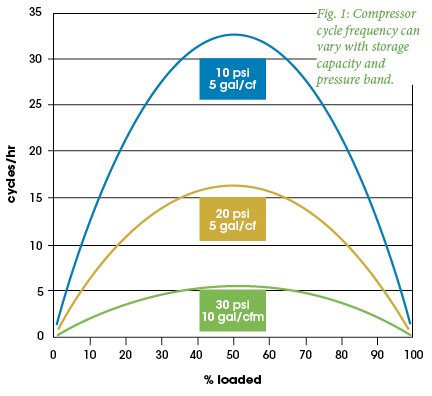

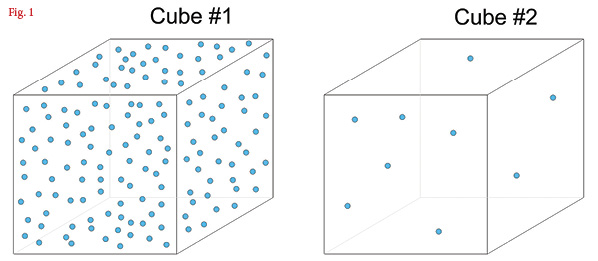

A compressor’s load and unload frequency is governed by the amount of storage receiver capacity it has to work with, the width of the compressor pressure setpoint band, and the percentage loading of the compressor (see Fig. 1 for an example comparison). Often the default storage tank recommended by the supplier, or the amount of storage that comes attached to a small compressor, is too small to limit the number of starts per hour if a compressor is set to turn off between cycles.

For example, a 60-cfm compressor may be installed with a storage tank of 60 gallons and run with a 10-psi pressure band. If this were the case, the compressor cycle frequency at 10% loading would be 58 per hour. If allowed to run start/stop, the number of cycles would far exceed the maximum allowed. But if a 600-gallon receiver was used and the compressor set to a pressure band width of 30 psi, the number of cycles per minute would fall to under two per hour. In fact, even if this compressor were operated at 50% loading, where the number of cycles is the greatest, the number of starts per hour would be less than six.

This, therefore, is part of the answer to the problem. If you are replacing your shop reciprocating compressor with a screw, you must install it with larger than normal storage and use a wider than normal pressure band to ensure it doesn’t cost you additional power. You must also ensure the compressor control is “smart” enough to turn the compressor off between cycles rather than running unloaded. (For more information, read “Is Your Compressor Control Smarter than a Four Year Old?” in the Tech Directory 2014 issue.)

Reinforce your industry expertise with a Pneumatic Mechanic, Technician, or Specialist certification. Apply online at www.ifps.org.

By Ron Marshall for the Compressed Air Challenge. To learn more about compressor control, consider taking part in Compressed Air Challenge’s next Fundamentals of Compressed Air Systems webinar. Go to www.compressedairchallenge.org to find out how.

Your chart shows a deep research and a very detailed look. To purchase a suitable air compressor, is not easy. You need to care about such things as: the use, noise, volume, weight …

Great job! ^^

The Manufacturer has a good technique where it is used to load and unload the frequency that can be defined by the amount of storage present in it.

A screw compressor will usually output its rated air (pressure and flow), straight from its discharge nozzle, but the reciprocating compressor will require a receiver to stabilize the air and build up pressure.

Wondering if screw compressor will necessarily require a receiver in a continuous duty, where water in the system isn’t a problem.