Steel Scrap Compactor Eject Cylinder Running Slow

By Robert Sheaf, CFPAI/AJPP, CFPE, CFPS, CFPECS, CFPMT, CFPMIP, CFPMMH, CFPMIH, CFPMM, CFC Industrial Training

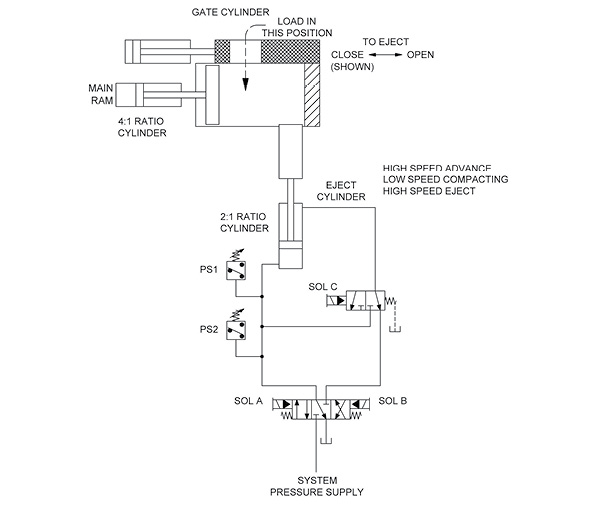

We received a call from a stamping company complaining about a large compactor’s “ejection cylinder” running slow. When our teammate Brian Szuch arrived, he found the cylinder’s function was also part of the compacting circuit.

After the main ram cylinder reached its maximum extension, the side ejector cylinder was designed to advance at high speed using a regeneration circuit, then slow down when the pressure switch PS-1 was tripped, taking it out of “regen.” When pressure switch PS-2 tripped, the gate cylinder would open the gate and the eject cylinder would eject the bail in high speed “regen.”

The problem was the eject cylinder extending at low speed and only going to high speed when ejecting the bail from the compactor.

Any idea what caused the problem?

See the solution

The slow speed problem with the compactor was caused by the pressure switch PS-1. Its contacts were fused together signaling to the PLC that the cylinder was meeting maximum compacting resistance.