Strong, Tough, and Reliable: Linear Displacement Transducers Take on the Most-Demanding Applications

By Blake Cawley, Product Manager, AMETEK Factory Automation

The importance of automation is greater than ever, as is the role played in automation by linear displacement transducers (LDTs). Today’s industrial challenges often involve pounding, continuous vibration, high pressure, extreme temperatures, and relentless cycling. LDTs have proven to provide accurate, reliable, absolute position feedback under extreme conditions in the most-demanding industrial environments, while, at same time, delivering value, easy set-up, and flexibility.

A range of automation solutions can provide accurate, continuous position feedback, but LDTs incorporating advanced magnetostrictive technology can provide precise, accurate, and absolute non-contact position feedback down to one-micron resolution. The technology itself is not new, nor is it rocket science. However, most importantly for many industrial applications, it is extremely rugged. LDT sensors can be packaged to survive the most hostile industrial environments, while performing reliable, repeatable, and accurate linear measurements.

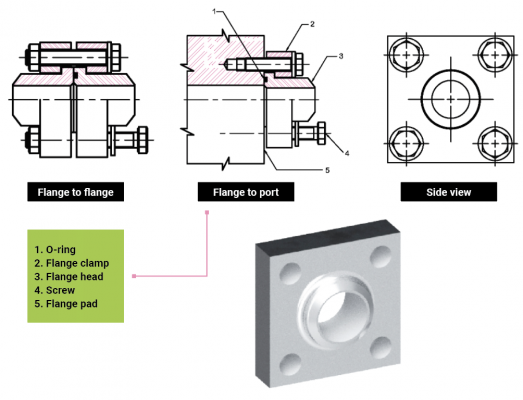

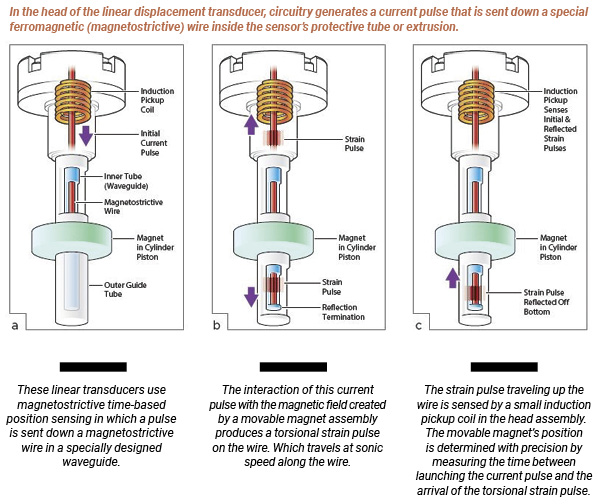

Magnetostrictive technology relies on the same physical principles that allow motors and generators to operate. This is basically how it works. In the head of the LDT is circuitry that generates a pulse of current that is sent down a special ferromagnetic (magnetostrictive) wire inside the sensor’s protective tube or extrusion. Outside the tube is a movable magnetic target. When the pulse interacts with the magnetic field, it generates a torsional twist that travels along the length of the wire at a fixed rate of speed that can be precisely measured.

The position of the magnet can be determined by measuring the time between the launch of the current pulse and the arrival of the torsion strain pulse. No direct contact is involved, and, along with that, absolutely no wear on the sensing element.

While many linear automation solutions provide accurate continuous linear position feedback, the most traditional approach uses an analog signal feedback to an analog input module or drive. Analog signals are limited by the resolution of the sensor and the input module. In addition, signals are prone to degrade over long cable runs, and each axis needs its own dedicated cable.

LDT users have overcome those shortcomings with Synchronous Serial Interface (SSI) sensors. SSI LDTs can provide serial-clocked output of binary or Gray code positional data with one-micron resolution regardless of stroke length of the sensor or the length of the cable run. The displacement value, or position, is encoded into 24-, 25- or 26-bit formats and transmitted at high speeds.

Synchronization in a closed-loop system is relatively easy. A clock-pulse train from a controller is used to shift out sensor data. One bit of position data is transmitted to the controller for each clock pulse received by the sensor. Absolute position data is updated continually by the sensor and converted by the shift register into serial information. SSI LDTs can interface seamlessly with virtually any programmable controller that can communicate with an SSI device. One disadvantage is the modules typically can’t handle more than two axis per module, and each axis requires its own cable.

Among the most recent technical developments are networked LDTs that provide non-contact feedback and one-micron resolution, while offering maximum installation flexibility and ease of use in highly demanding networked industrial applications. These include pulp and paper, steel mills; lumber and forest products equipment; primary and secondary metals processing, such as stamping, roll forming and die-casting; tire and rubber, plastic injection-molding; and material handling machinery.

LDTs typically find application in a broad range of industries that require a machine or a piece of equipment to move in a linear fashion and feedback to automate it. LDTs are available in two package styles: the traditional Rod Style package suitable for installation into hydraulic cylinders and the Profile Style that incorporates similar electronics, but houses those electronics in an aluminium extrusion for ease of mounting.

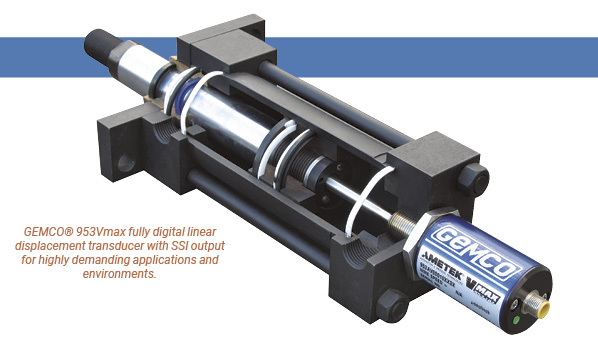

Some Rod Style transducers are rated for up to 30 Gs of vibration and 1,000 Gs of shock, and are available in a wide range of outputs, allowing them to interface with a variety of host controllers. The choice of style depends on what works best for an application.

Rod Style transducers, for example, are preferred for hydraulic cylinders because of the LDT’s ability to withstand operating pressures up to 5,000 PSI that at times can spike to 10,000 PSI. For an LDT to operate properly in a hydraulic cylinder, it must be prepped to accept a Rod Style transducer. The cylinder piston must be gun drilled with a 12.7mm (half-inch) bore and the end cap machined to accept a linear transducer. A magnet also must be added to the cylinder’s piston.

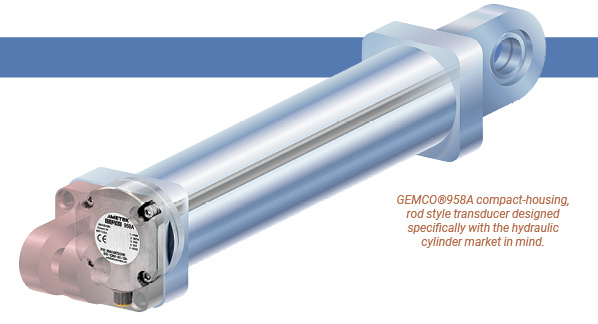

On Clevis style cylinders, there is typically no room to mount a traditional Rod Style transducer. In this instance, there is an embedded-style transducer package that totally encapsulates the LDT inside the cylinder, protecting it from outside conditions and making it resistant to contaminants and other hazards. This compact housing LDT is the ideal for agricultural, construction, and mining equipment and commercial vehicles.

LDTs also have become smarter. Many models are now field configurable for output type, zero position, counting direction, position and velocity format, and resolution. Some, more-sophisticated sensors can even support wide ranging power supplies (7VDC to 30VDC), so the same unit can be used in both stationary and in mobile applications. These wide-ranging power supply capabilities allow newer linear transducers to be backward compatible with older generations that need a +/-15V bipolar supply. Diagnostic LEDs also have been added to aid with troubleshooting, and standardized cables, such as 12mm Euro-style cord sets, are available as an option, helping to reduce installation costs.

Automatic gain, or AGC, was introduced years ago to help compensate for different style magnets found in hydraulic cylinders. On power up, most sensors are now able measure the strength of the magnet and automatically adjust its internal signal lengths to match the user’s installed magnet. This is a benefit in hydraulic cylinder applications in which the brand of installed magnet is a different from that of the sensor.

Linear displacement transducers have proven their value over the years by delivering reliable position measurement for a broad range of applications. Furthering their application in industrial automation has been the ability of LDT makers to design and build sensors that meet and exceed customer expectations in the harshest and most-demanding circumstances.