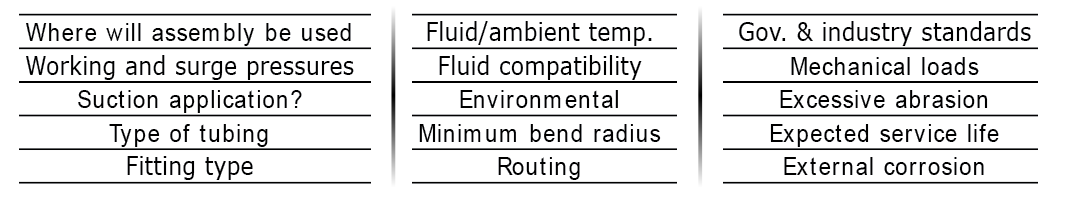

The STAMPED Method for Selecting Tubing and Fittings for a Metal Tube Assembly

The acronym STAMPED, as used for hose assemblies, is equally as important to use when developing tube assemblies. The same factors apply; only the fabrication and installation will vary. Flow and pressure charts can be found from the same technical references.

Size of the tubing is based on:

1. Flow (GPM)

2. Flow velocity (ft/sec)

3. Pressure

4. External corrosion

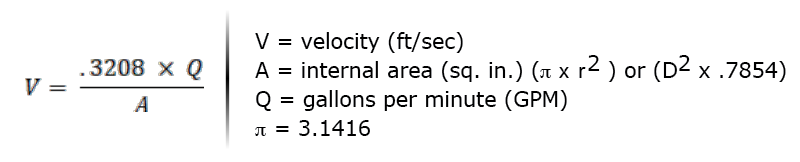

All hydraulic tubing is measured on the outside diameter (O.D.). The flow velocity is based on the gallons per minute (GPM) flowing through the tube. This can be calculated or found on charts and in technical references.

Pressure is included in sizing here as well as under the “P” later on in STAMPED. Flow losses (pressure drop) can affect sizing the tubing. Length of line and configuration (elbows and number of fittings) can add to pressure losses dictating a larger tube I.D. Low temperatures can also affect viscosity, which in turn will affect pressure drop. Wall thickness at bent tube sections will have reduced wall size. This will require the designer to determine the amount of reduction based on the bend radius and to recalculate allowable working pressure for the particular bend. On some applications where corrosion is anticipated, the life of the system can be extended by increasing the wall thickness to compensate.

Temperature can be a factor with tubing and fittings, but usually not until temperatures are extreme (350° F to -45° F). High and low temperatures can affect O-rings in fittings and the selection of tubing.

Application: Determine where the new or replacement tube assembly is to be used. Most often, only a duplicate of the original will be required, provided the original assembly gave acceptable service life. To fulfill the requirements of the application, additional questions may need to be answered such as:

Material: Tube selection and fittings must be compatible with the fluid to be circulated in the system, as well as the environmental conditions.

Pressure: When selecting metal tube, it is vital to know the working pressure, including pressure spikes. Pressure spikes greater than the published working pressures will shorten the system service life and must be taken into consideration. Published tube working pressures must be equal to or greater than the system pressure. Thinning of the tube wall at bends must also be considered.

Burst pressures are reference pressures intended for destructive testing purposes and design safety factors only. Typically, for dynamic hydraulic applications, the minimum burst pressure rating is four times that of the maximum working pressure rating.

Ends: Identify the tube end fittings using manufacturers’ catalogs.

Delivery: Availability, time to assemble, special packaging, shipping, and documentation.

Test Your Skills

1. All hydraulic tubing is measured by its:

a. O.D.

b. I.D.

c. Wall thickness.

d. Material hardness.

e. Material type.

2. Anticipating a corrosion problem one could:

a. Increase volume.

b. Decrease volume.

c. Increase pressure.

d. Decrease wall thickness.

e. Increase wall thickness.

EMS applies an in-depth penetrating electrical present towards the locations with your again that happen to

be creating your discomfort. They’ll suggest you perform

these workouts daily to strengthen and reinforce your core.

No matter you need bifocal sunglasses which might

be stated in aviator style, rectangle style or big style, firmoo

can satisfy you with both high quality and cheap prices.