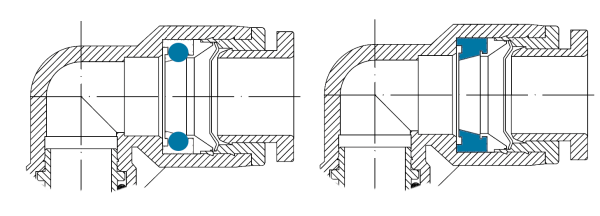

Pneumatic Versus Vacuum Component Design

By Dane Spivak, Engineering Manager, Davasol Inc. A pneumatic system is defined as an application that uses a positive pressure gas to perform an operation. A …

Test Your Skills: Considering Component Capability

Some fluids with very good lubricity and viscosity characteristics may prove caustic to the material in pumps, actuators, or valves, especially when hot. There …

All About Vacuum: Sizing Vacuum Components

By Dane Spivak, Engineering Manager, Davasol Inc. The design principles of most fluid power systems and vacuum gripping systems are governed by flow rate and …

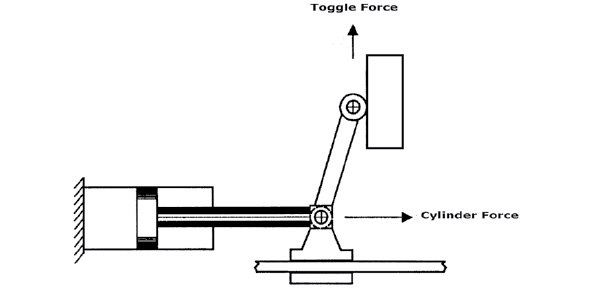

Select Components for Hydraulic Systems: Calculating the Thrust for a Toggle Mechanism

Toggle mechanisms are used where high locking forces are required. Die casting machines, injection molding machines, and coining machines all make use of …

Storage of Pneumatic & Vacuum Components

The primary materials (excluding electronics) in industrial pneumatic and vacuum components subject to degradation under adverse conditions are the elastomers …

Why Machinery Builders Need Component Reliability Data

As the title suggests, fluid power components are supposed to have some sort of measurable reliability. And that data is available – yes? Well, not right …

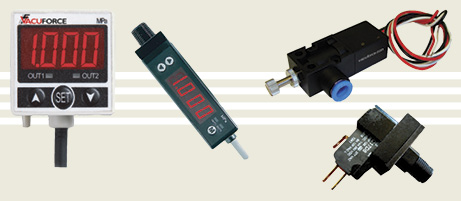

Basic Vacuum Components

Over the last 30-something articles I’ve written for the Fluid Power Journal, I have discussed various product overviews and specific applications offering …

Hydrostatic Transmission Components

HYDROSTATIC TRANSMISSION COMPONENTS today are of such high quality and efficiency they don’t allow enough exchange of oil in the loop to keep temperatures …