Features

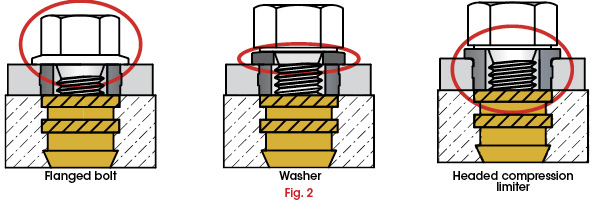

How to Ensure Bolted Joint Integrity When Using a Compression Limiter in a Plastic Assembly

Compression limiters are used to protect plastic components in bolted joints and maintain a threaded fastener’s clamp load by eliminating plastic creep. To …

BAUMA 2016

The Trade Fair for Construction Machinery, Building Material Machines, Mining Machines, Construction Vehicles, and Construction Equipment April 11-17, 2016 / …

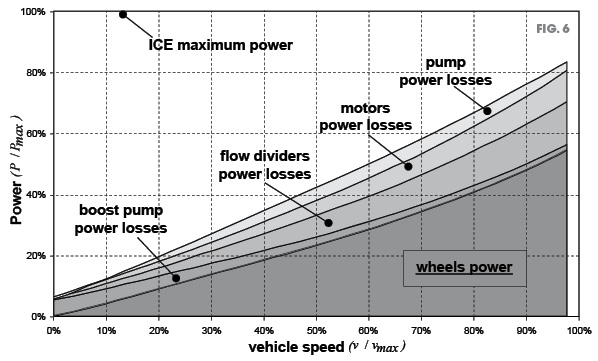

Traction Control Using Torque Divider

Controlling traction in hydraulic propel applications can be a slippery situation. Good traction demands all driving wheels take an equal share of propulsion …

2016 Mobile Q&A

Ken Baker is the CEO of Bailey International, with headquarters in Knoxville, Tenn., and locations in Victoria, British Columbia; Kansas City, Kans.; Reno, …

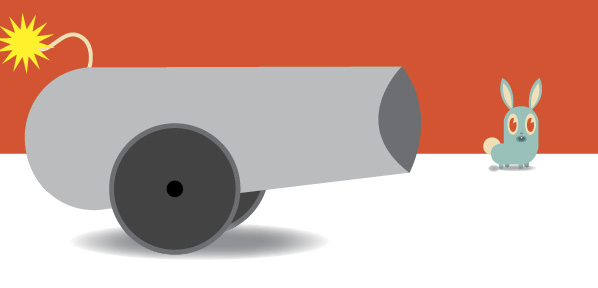

Don’t Bring a Cannon to a Rabbit Hunt

How much power do you hold in that air gun in the palm of your hand? If you are the typical compressed air user, you will have no idea; most people think …

Celebrate Fluid Power Professionals’ Day 2016

Thank you to all participants who have entered the photo contest. It’s time to vote for the People’s Choice Award. You and your family/friends can vote …

Bolt Tensioning Device at Power Station Improves Safety and Usability

By Doug Green, Publisher, Asia Manufacturing News Two major power stations in South Korea have installed Technofast’s hydraulic CamNut EziJac bolting system, …

Fluid Power Electronic Controls Specialist (ECS) Certification Upgrade

The IFPS Certification Committee is proud to release a revised, enhanced, and fine-tuned version of the ECS. The IFPS defines a Fluid Power Electronic Controls …

HY-TRAX® Fluid Sampling Systems

In the past, unplanned equipment downtime and its associated costs resulted from a lack of visibility to real-time hydraulic fluid cleanliness conditions. …

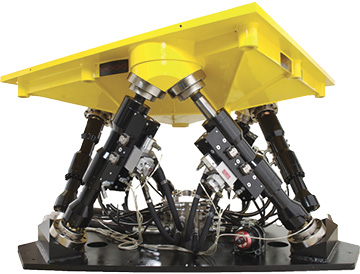

A Planned Outage Spurs a Unique Approach for Turbine Maintenance

When power plant managers realized their scheduled window for a steam valve outage was challenging, engineers came up with a new tactic for servicing a dozen …

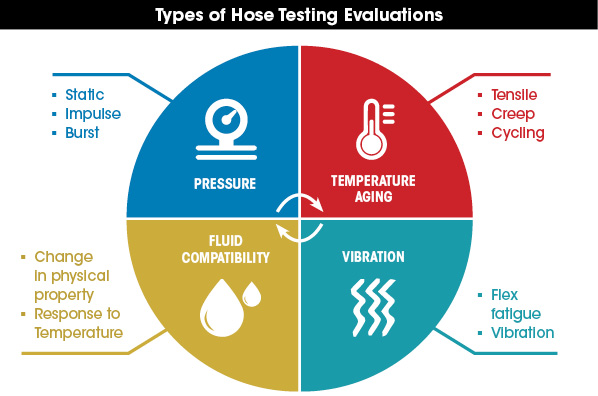

Hose Testing Methods for Optimal Performance

Predicting the life of a hose and determining the source of a failure can be difficult. Understanding how or when a failure occurs is time, temperature, and …

The Dirty 30

A tool supplier called one day asking for help. A fiberglass plant was experiencing problems with one of its compressed air powered tools, a circular saw used …

Rough-Terrain Telescopic Forklifts Keep Expeditionary Military Operations Up and Running

DuraForce Pumps from Eaton Equip the RT022 forklifts with reliable, precise control and maneuverability, even in difficult terrain. Kalmar specializes in port …

Valve Positioners Offer Improved Control Valve Performance

Valve positioners have changed the way actuated control valves respond within a process control loop. By adding either a pneumatic or electro-pneumatic …

Hydraulics are Fun!

Eaton’s Event Introduces 27 Minority Students to Hydraulics Training and Career Paths Eaton sponsored the second-annual “Hydraulics are Fun!” event …

6 Surprising Capabilities of Modern Hydraulics

Anyone gaining only a superfluous familiarity with fluid technology can easily underestimate the performance and intelligence of modern hydraulics. Who would …

You Can Influence the Fluid Power Industry with Chapter Outreach

By Scott Gower, CFPS Talking to others about oneself is natural. Explaining one’s career in fluid power to the Average Joe is often complex, and the …

Utilization of Sensitive Compliant Lightweight Robot Arms for Hydraulic Valve Assembly

Today’s industrial robots are well-fitted for the needs of mass production. They can perform repetitive tasks with high performance within a well-structured …

2015 IFPS Annual Meeting

Click on images to enlarge

IFPS Pathways to Success

To keep pace with the broad and ever-changing needs of industry, the International Fluid Power Society provides many specific and complementary certifications …

Storage of Pneumatic & Vacuum Components

The primary materials (excluding electronics) in industrial pneumatic and vacuum components subject to degradation under adverse conditions are the elastomers …

Gestamp North America: Learning, Development, and Certification for a Global Industry

Gestamp’s strength as a global organization relies upon its people’s values and professional skills. We encourage continuous learning through networking …

The IFPS and the Military

G.I. Bill Information The IFPS is an approved organization by the United States Department of Veterans Affairs (VA) to provide reimbursement for certification …